The AFL Oil Stop Valve is fabricated from non-corrosive PVC or stainless steel. Standard sizes are 4”, 6” 8”, 10” and 12” discharge piping. Larger piping systems can be accommodated by manifolding units together. Optional screening can be provided if necessary to prevent the discharge of large floating solids. An optional slave valve is recommended if evaporation or leaky manholes allow the main float to close. Once rainwater enters the manhole, the slave valve will open and equalize the pressure allowing the main float to reopen.

The OSV is designed for easy installation to any existing separators, catch basins or manholes. AFL also provides the OSV prepackaged in a fiberglass or concrete catch basin or as an option on AFL’s oil water separators. Consider the OSV for those applications where oil spills are possible, but unpredictable such as electrical transformers, oil storage areas, and transportation fueling systems. The Oil Stop Valve is the most cost effective method to prevent a major disaster.

AFL Oil Stop Valves can be used as part of your compliance plan to meet requirements of EPA 40CFR112 SPCC- Spill Prevention, Control, and Countermeasure. Click here for more information regarding the SPCC

Chapter 3 of the EPA’s SPCC guidance for regional inspectors discusses the use of alternative technologies that provide environmental protection equivalency to a manually operated valve. Click here to access the EPA SPCC GUIDANCE FOR REGIONAL INSPECTORS. (PDF , 921pgs)

NOTE: The EPA requires that the facility or facility operator must have a documented plan for compliance to the SPCC approved by a professional engineer.

The OSV in Action:

The OSV has only one mechanical moving part, a ballasted float set at a specific gravity between that of oil and water (.95 or less). When an oil spill occurs, the float loses buoyancy as the oil level increases until it finally seats itself on the discharge port. Thus the oil spill is confined.

CHOOSING THE PROPER VALVE TYPE AND MATERIAL

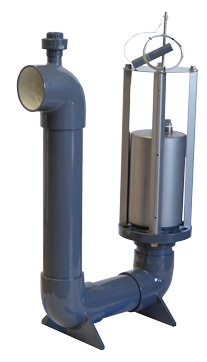

PVC

PVC models are the most economical way to prevent bulk hydrocarbon spills.

Corrosion resistant PVC construction is an ideal choice for warm climates.

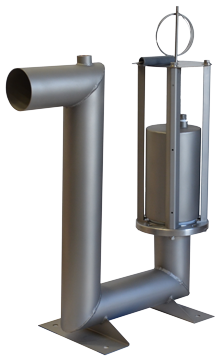

Stainless Steel Not Extended

Used in lieu of PVC units in colder climates, which may eliminate the necessity for an electric freeze protection package.

Stainless Steel Extended

The best option if fire is possible. By extending the pipe thru the sump wall, there is no connection inside the sump to burn and fail.

Chapter 3 of the EPA’s SPCC guidance for regional inspectors discusses the use of alternative technologies that provide environmental protection equivalency to a manually operated valve. Click here to access the EPA SPCC GUIDANCE FOR REGIONAL INSPECTORS. (PDF , 921pgs)

NOTE: The EPA requires that the facility or facility operator must have a documented plan for compliance to the SPCC approved by a professional engineer.