RGF® Environmental Group Initiates Research Project to Enhance Filtration and Inactivation of Radioactive Particulates

Port of Palm Beach, FL (May 5, 2022) RGF® Environmental Group, Inc. is a world leader in Air Treatment Technologies. In addition to proprietary active air treatment systems for residential and commercial applications, the company manufactures FDA approved High-Efficiency Particulate Air (HEPA) filter systems for use in health care applications. HEPA filters are rated to remove greater than 99.97% of airborne particles that measure 0.3 microns and larger and are widely used in hospitals, schools, aircraft and commercial buildings. True HEPA filtration is widely recognized as a safe, practical and effective technology for cleaning the air.

HEPA filtration technology was originally developed during the Second World War to protect scientists working on nuclear weapons. After the war, the technology was adopted by both the nuclear power industry and nuclear weapon testing and is used extensively to prevent the release of radioactive particles into the environment from nuclear power plants.

RGF® originally designed, built and tested a radiation filter/neutralizer 21 years ago for a multi billionaire’s office in New York after 9/11. He was worried that a tactical nuclear attack may be next. RGF® tested the unit and installed it in his office. Thank God it has never been needed for a nuclear attack so RGF® never went into production. Obviously, things have changed in the world for the worse and a nuclear attack is of concern! Even a tactical nuclear weapon will create a radiation fallout cloud that will travel around the world with weather patterns.

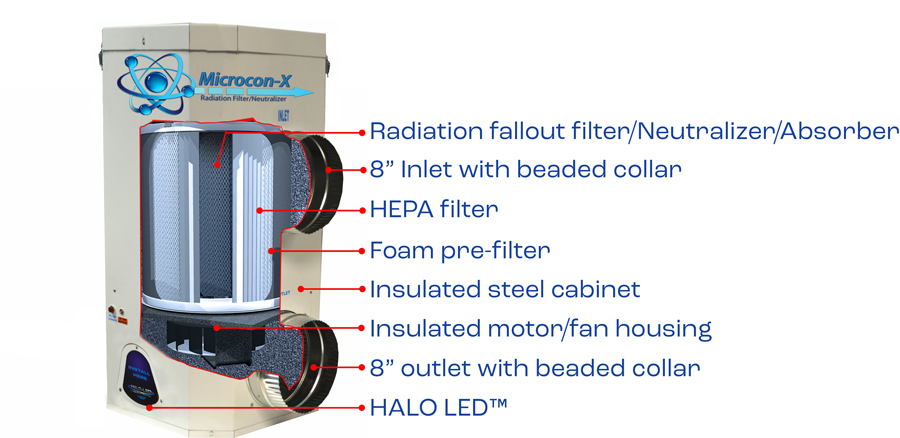

An RGF® research and development project has been in testing for years to combine our ETL/FDA approved state-of-the-art HEPA filtration technologies that utilize our RGF® ETL approved Photohydroionization® (PHI) and Bipolar Ionization, carbon, boron, and RGF’s proprietary activated minerals for the effective filtration and inactivation of radioactive particles and gases, also ozone.

This project is designed to develop devices for use in homes and commercial establishments to reduce the risks associated with radioactive fallout that may occur as a result of a natural disaster, a deliberate nuclear attack, or in some locations occur naturally.

Dr. James Marsden, RGF’s Executive Director of Science and Technology, is leading the project in cooperation with the company’s engineers who have extensive nuclear weapon testing and nuclear power generation safety experience. In announcing the project, he stated that, “By combining proprietary RGF® air treatment technologies with true HEPA filtration, the risks associated with radioactive fallout can be substantially reduced in homes as well as commercial buildings.” Although this may seem premature, RGF® has always been ahead of the time throughout their 37-year history. Better to be safe and prepared than sorry. RGF® has the Microcon-X in-duct system and stand-alone floor models in limited production for field testing.

References

Journal of Physics: Conference Series

THE FOLLOWING ARTICLE IS OPEN ACCESS

Lessons learnt over 30 years of air filtration in the nuclear industry

J Vendel1, J C Laborde1, N Michielsen1 and F Gensdarmes1

Published under license by IOP Publishing Ltd

Journal of Physics: Conference Series, Volume 170, NANOSAFE 2008: INTERNATIONAL CONFERENCE ON SAFE PRODUCTION AND USE OF NANOMATERIALS 3–7 November 2008, Minatec, Grenoble, France

Citation J Vendel et al 2009 J. Phys.: Conf. Ser. 170 012026

How Foolproof Air Cleaning Systems at Nuclear Power Plants Protect Public Health

Jacqueline DiChiara – Harvard School of Public Health

www.hsph.harvard.edu/ecpe/air-cleaning-systems-nuclear-power/

The Need for Maintaining Nuclear Air-Cleaning Systems Properly to Protect Public Health and Safety

Lisa D. Ellis – Harvard School of Public Health – 2020 www.hsph.harvard.edu/ecpe/maintaining-nuclear-air-cleaning-systems-protect-public-health-safety/

About RGF® Environmental Group, Inc.

RGF manufactures over 500 environmental products and has a 37+ year history of providing the world with the safest air, water and food without the use of chemicals. RGF is an ISO 9001:2015 certified research and innovation company, holding numerous patents for wastewater treatment systems, air purifying devices, and food sanitation systems. Situated in the heart of the Port of Palm Beach Enterprise Zone, RGF Headquarters span 10 acres, with 200,000 square feet of manufacturing, warehouse and office facilities. RGF’s Lakeland, FL facility adds over 40,000 square feet for back-up production and lamp production. RGF continues to upgrade its facilities, creating an increased vertical approach to manufacturing, further allowing the company to provide the highest quality and best-engineered products on the market.